- |

- Chinese

The 25th China International Petroleum & Petrochemical Technology and Equipment Exhibition will be held on March 26-28, 2025 at New China International Exhibition Center, Beijing, China.

Come and meet WZ Magnetic at Booth:W2565, Hall W2.

Shanghai WZ Magnetic Industry Co., Ltd. has accumulated rich experience and advanced technology in the manufacturing of magnetic sucker and magnetic filters, dedicated to providing efficient and reliable magnetic solutions for the Petroleum and petrochemical industry, significantly enhancing production efficiency and reducing operating costs.

Our magnetic suckers are designed to firmly hold metal objects in various industrial environments, offering strong durability and stability. They are widely used in equipment maintenance and component assembly, providing customers with ease of use and safety assurance.

The magnetic filters can efficiently remove metal impurities generated during the petroleum storage process, protecting equipment and extending its lifespan. This solution reduces equipment failure rates and downtime, thereby improving overall production efficiency.

We are committed to driving technological innovation, and continuously investing in research and development to ensure our products remain industry leaders in performance, durability, and reliability. We work closely with clients to customize solutions based on their specific needs, ensuring the successful implementation of every project.

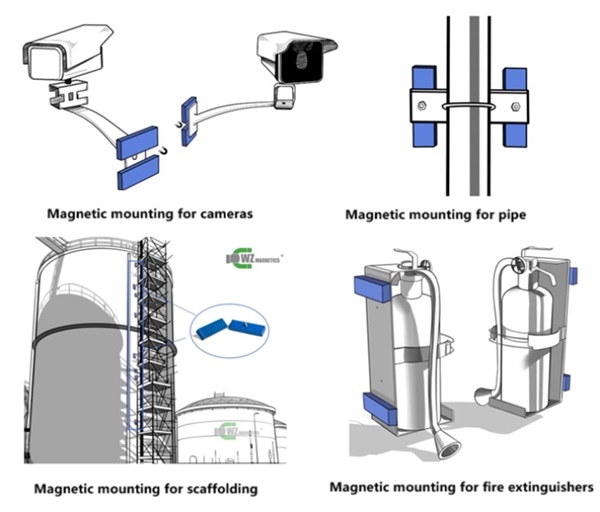

Magnetic mounting has multiple advantages (safety, ease of use, and wide application):

1.Technical transformation, inspection, and maintenance in hazardous areas, tank areas, and areas with natural gas leakage: Magnetic mounting eliminates dangerous actions such as welding, drilling, and other risky procedures that involve fire hazards.

2.The magnetic surface is insulated with rubber and is elastic, preventing damage to the contact surface. It does not produce sparks or arcs during attachment, making it simple and easy to use.

3.Wide range of applications: Magnetic mounting can be used for fixed installations in both safe and hazardous areas, construction zones, and for wiring, cable trays, ladder installations, lighting, fire extinguishers, cameras, electrical boxes, as well as scaffolding, footrests, protective fences, seats, helmets, workwear, safety ropes, and more.

Magnetic Filters

1.Efficient Removal of Ferromagnetic Contaminants: Magnetic filters can effectively capture and remove ferromagnetic particles from oils or gases, such as iron filings, wear particles, and other metal impurities, protecting equipment and extending its lifespan.

2.Reduced Equipment Wear: By removing metal particles generated from wear, magnetic filters help reduce the wear on pumps, valves, and pipelines, lowering maintenance costs and downtime.

3.Improved Product Quality: By eliminating impurities, they enhance the purity of raw materials and finished products, improving the quality of the final product and ensuring compliance with industry standards.

4.Cost Savings: By decreasing the frequency of filter material replacements and reducing the risk of equipment damage, magnetic filters can lower operational costs.

5.Environmental Friendly: Magnetic filters do not require the use of chemicals, reducing environmental pollution and aligning with sustainable development principles.

6.Simple Maintenance: Magnetic filters are generally designed for easy cleaning and maintenance, making them user-friendly and improving work efficiency.

7.Wide Applicability: They can be used for various oils, gases, and chemical liquids, adapting to different process requirements.

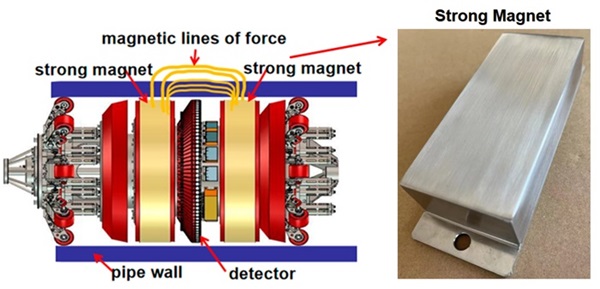

The Role of Strong Magnets in Pipeline Inspection Devices (PIG):

1.Improving Cleaning Efficiency: Strong magnetic forces can attract and remove ferrous debris, rust, and other particles from within the pipeline, making the cleaning process more thorough.

2.Detection Function: In addition to collecting debris, magnets in pipeline inspection devices are used for magnetic detection, especially through Magnetic Flux Leakage (MFL) technology. As a PIG equipped with strong magnets moves through the pipeline, the magnets magnetize the pipeline, forming a closed magnetic circuit linked by a magnetic yoke. At defect locations in the pipe wall, magnetic flux lines leak into the air, creating magnetic leakage that is detected by magnetic sensors. Data collection and analysis allow the identification of defects and their locations within the pipeline, such as cracks on the pipe wall.

3.Suitability for Hazardous Areas: Magnets can securely position or stabilize the PIG without producing sparks or friction, making them especially suitable for use in flammable or explosive hazardous areas.

4.Cost Savings: Magnetic detection can promptly identify potential issues in pipelines, which is particularly valuable for the maintenance of aging pipelines. Maintenance can be performed as needed, enhancing pipeline safety management and reducing maintenance costs.